Over the past three months we have all come to know more than we ever wanted to know about face masks. There was a time when most of us encountered face masks only as themes for movies (think Antonio Banderas in Zorro and Jim Carrey in The Mask) or as gloopy brown stuff applied to the face in an effort to recapture the glow of youth. Happy days.

Thanks to the coronavirus pandemic, face masks have become mandatory not only to protect workers in industry but also citizens walking the streets of many Western cities. Some are wearing surgical masks, others favour the N95 while yet more are re-fashioning old t-shirts like contestants in the Great British Sewing Bee. Personal Protective Equipment (PPE) comes in many shapes and sizes and today PPE is a hot topic.

For many years, the UK Health and Safety Executive (HSE) have established guidelines and requirements for the effectiveness of commercial face masks. It is crucially important that workers in hazardous dusty environments are safeguarded against ingesting particles that can get lodged in the lungs and cause discomfort in the short term and serious diseases in the longer term. Filtering Face Piece (FFP) masks are classified into three categories: FFP1 (>80% filtering), FFP2 (>95% filtering) and FFP3 (>98% filtering). Classification relies on practical testing of masks but the actual efficiency and effectiveness of a mask are determined by: materials and design; the fit to the face; and the methods available to test for very low levels of solid particles and aerosols.

Raman microscopy has recently been shown to offer a huge improvement in the Limit Of Detection (LOD) of particles actually inside a FFP3 mask. This matters for the most protecting respirators and for the detection of the smallest particles (10-200 nm) such as diesel exhaust soots and viruses. Earlier this month, researchers at the HSE and Sheffield Hallam University reported in the journal Analytical Methods that Raman microscopy improved the LOD of particles infiltrating an FFP3 mask from around 5.5 μg using conventional X-ray detection to 0.26 μg on similar sized test filters.

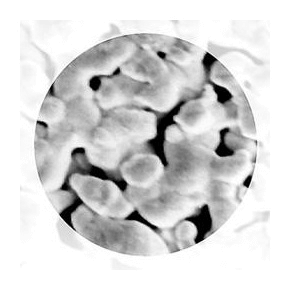

Chemical analysis of particles is tricky, as any analyst working on micro-plastics in water or airborne pollution will tell you. Peter Stacey and his group at HSE developed and carefully tested different particle sampling methods. PVC test filters were placed inside FFP3 masks fitted to breathing dummies, which were then exposed to air containing silica particles. Silica particles are an established cause of silicosis lung disease and are a good subject for analytical technique development.

PVC filters are convenient for sampling but silver filters give lower background signals for Raman microscopy and are already used for X-ray analysis. Therefore the particles were washed from the PVC filter and transferred to silver filters for final analysis. This step in the method offered the possibility to control the concentration of the collected particles on the surface prior to analysis. Taking up to 60 areas on the surface of the filters, the Raman method quickly gave a quantitative determination of the number of silica particles. As a technique that gives a molecular ‘fingerprint’ of the particles, Raman can also easily identify the kind of silica (quartz, cristobalite or amorphous), which is less easy with X-ray diffraction.

Another future refinement of the technique could be the detection and identification of unknown particles by searching the Raman spectra of particles against a spectral database. Combining the advantages of novel materials, clever mask design and ever more sensitive analysis will make PPE more personal and more protecting in the future. New analytical technique development is playing its part in the fight against airborne pollution and disease.

The published article on the new Raman analytical method can be found at the Royal Society of Chemistry Analytical Methods .

You can see a short video of a FFP mask test demonstration here.