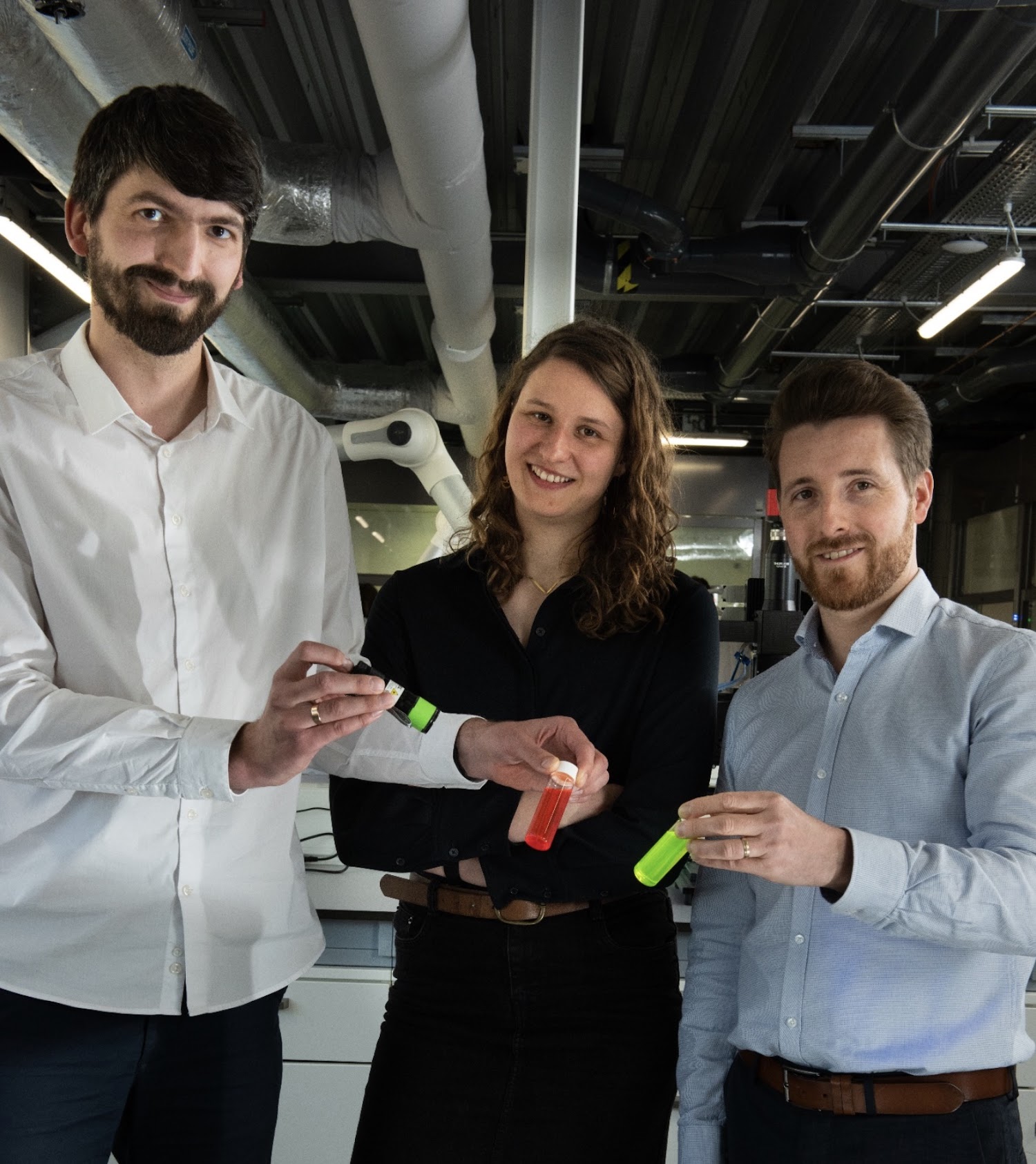

Small is beautiful. Small and brightly coloured is very beautiful indeed! Belgium companies QustomDot BV and chip designers MICLEDI Microdisplays BV have teamed up to produce a major advance in mass producing display devices for augmented and virtual reality (AR and VR) applications.

MicroLED displays are emerging as possibly the best devices for AR and VR applications in the metaverse. They are bright, high resolution and have low power consumption. Gallium nitride microLED sources are small and bright but typically emit blue light. Great for a blue display but what about red and green pixels? This is where the QustomDot technology comes in. QustomDot have developed quantum dot materials which absorb blue light and re-emit green or red light.

So why are these quantum dots special? Cadmium sulphide (CdS) or selenide materials have been around for some time but cadmium is problematic in the environment and avoided in new materials technologies. QustomDot have a solution (literally). Their indium phosphide (InP) dots have high efficiency and avoid the use of harmful cadmium. By controlling the size of the nano-particles, they are able to change the colour of light the quantum dots emit. InP based dots can be produced not only in solutions but also transferred to surfaces such as those of gallium nitride microLEDs.

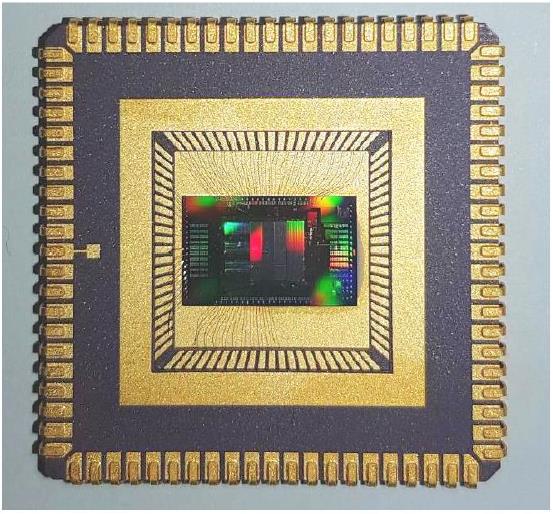

Partners MICLEDI, a spin-out from the Belgian microelectronics hub at IMEC, are able to produce the required wafer-scale GaN microLEDs. The significance of the technology is that IMEC has decades of experience of advanced CMOS fabrication. CMOS technology can produce industry standard 12″ wafers with sub-micro resolution and alignment of transfers. Amazing.

Competing technologies based on less well-established materials currently produce 4″ wafers, with more development work required to scale-up. It remains to be seen which technology will finally win in the AR/VR marketplace.

Find out more about MICLEDI BV.

Find out more about QustomDot BV.

Find out more about Corbeau’s microLED inspection tools.